What do RTI’s products do?

RTI instruments are essentially divided into two categories; Acoustic Doppler Current Profilers (ADCP)

and Doppler Velocity Logs (DVL), described below.

ADCP – is a hydro-acoustic instrument or sonar device that is used to measure water velocities

in discrete layers over a certain range that is defined by the acoustic frequency. Essentially, the ADCP emits

a sound signal of a specific frequency and measures the return frequency that is received from backscatter via

particles in the water column to determine water velocity.

It is important to note that RTI has a special category of ADCPs that have an extra beam, a vertical beam, as well as an integrated pressure sensor and advanced processing technique. This instrument, in addition to velocity profiling, can be used to calculate first order waves statistics.

It is important to note that RTI has a special category of ADCPs that have an extra beam, a vertical beam, as well as an integrated pressure sensor and advanced processing technique. This instrument, in addition to velocity profiling, can be used to calculate first order waves statistics.

DVL – is a hydro-acoustic device that is used to bottom-track or process emitted sound signal

that return from the seafloor or river bottom. Using a DVL combined with a position fix (via GPS) and a compass

the DVL can be used for underwater navigation (i.e., Submarines, AUVs and ROVs).

What applications are RTI instruments used in?

ADCPs are typically used to measure discrete layers of velocity in the water column. The

instruments are used in oceanography and hydrology applications. For oceanography, systems are used installed

directly on the seafloor, looking up to measure currents, turbulence and waves parameters. In addition,

instruments used in oceanography can be used mounted on a mooring (looking up or down) or a surface buoy

(looking down).

DVLs are used for subsea and surface vessel navigation applications. DVLs are used for

navigation by tracking the bottom (seafloor, river bottom, etc.), vehicle velocity and direction for navigation

purposes – this is particularly useful when no GPS is available. Additional applications within navigation are

closed-loop control for station keeping, velocity-aiding of inertial navigation systems and towed vehicle

along/across-track velocity measurements.

I purchased an ADCP, but can I use it as a DVL?

YES. Considering the economic times, RTI understand flexibility and multi-use applications exist for ADCP/DVLs.

RTI believes the end user should be empowered to collect all types of data that is possible and repurpose the

Instrument if necessary. Using Pulse software, the user can program the instrument for the appropriate

application.

What is the difference between a Doppler piston product and a Doppler planar (phased) array?

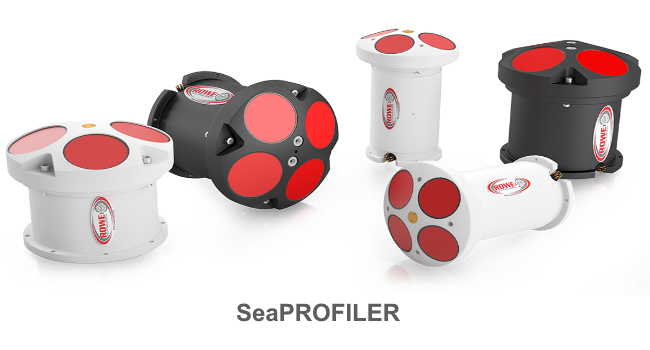

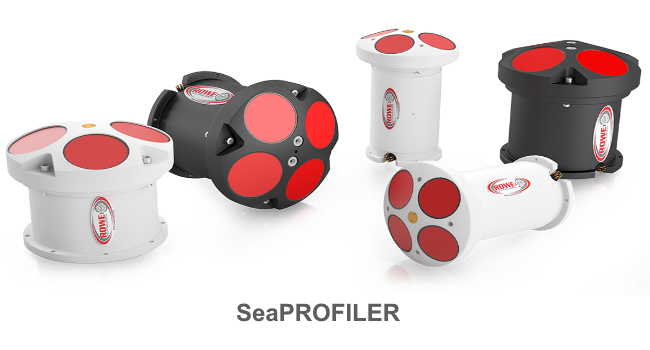

Doppler piston products have transducers that are fixed in the head of the instrument; each transducer can form

individual acoustic beams to make measurements. RTI Doppler piston products typically have 20° beam angles and

can operate at a wide range of acoustic frequencies. Below is an example of a Doppler piston product with eight

transducers/beams in red.

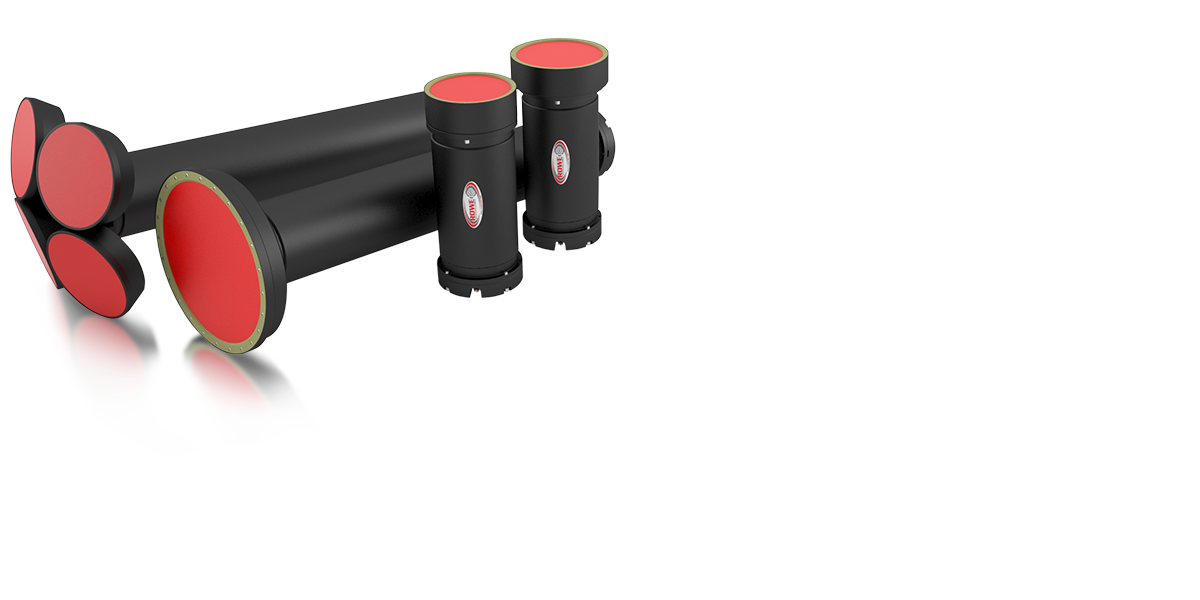

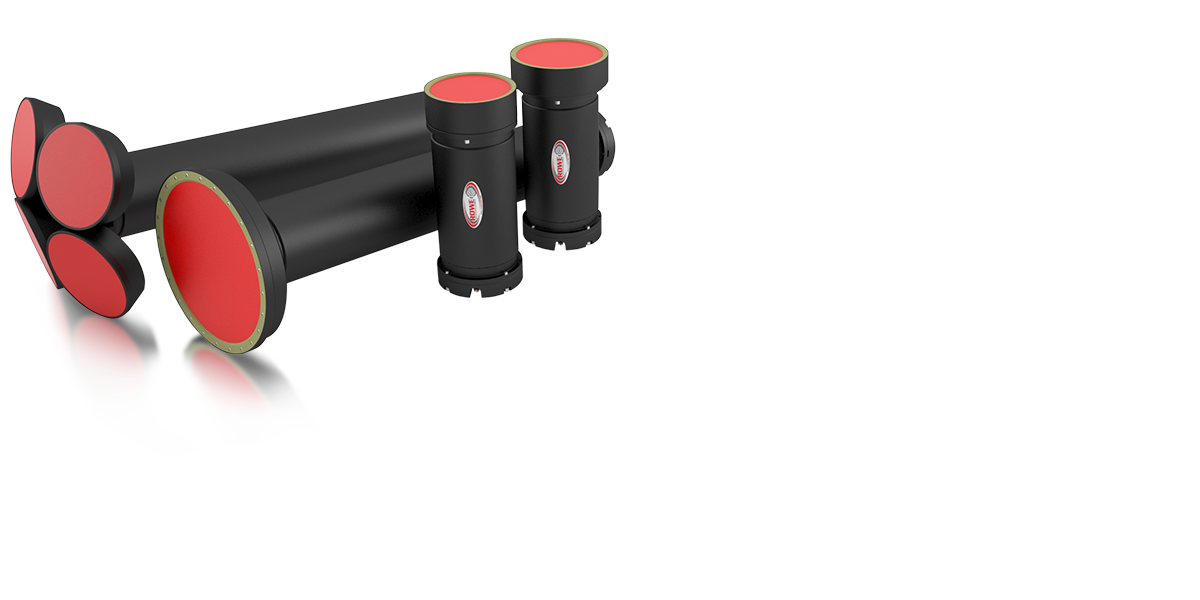

Doppler array products have one, flat-faced transducer, which has many elements that can form acoustic beams. Doppler array products are more flexible in programming as the array can form beams at 30° and 20° off of the vertical as well as a vertical beam (0° off of the vertical). In addition, Doppler array products have a more compact form factor due to the use of only one transducer. Due to the complexity of acoustic processing, Doppler array products are only used in lower acoustic frequencies (600kHz and lower). Below is an example of a Doppler array product, with its lone transducer in red.

Doppler array products have one, flat-faced transducer, which has many elements that can form acoustic beams. Doppler array products are more flexible in programming as the array can form beams at 30° and 20° off of the vertical as well as a vertical beam (0° off of the vertical). In addition, Doppler array products have a more compact form factor due to the use of only one transducer. Due to the complexity of acoustic processing, Doppler array products are only used in lower acoustic frequencies (600kHz and lower). Below is an example of a Doppler array product, with its lone transducer in red.

How many transducers/beams do Rowe Technologies use in their ADCP/DVLs Doppler piston products?

Traditional ADCP/DVL applications have 4 transducers to measure 3-axis (xyz) current profile, bottom track and

water track. ADCPs enabled for waves analysis have 5 transducers; the additional transducer is a vertical beam.

Dual frequency systems have 8 transducers, with 4 transducers corresponding the each frequency. Dual frequency

systems are essentially two instruments-in-one, providing increased velocity profile resolution when used as an

ADCP, and better near boundary bottom track information when used as a DVL. A hybrid of a dual frequency and

waves system is our SeaSeven. It will have 7 transducers. 3 transducer for the dual frequency system and a

vertical beam.

What are the typical power input and consumption for RTI systems?

High frequency systems (1200, 600 and 300 kHz) have 11-36 VDC input requirements and a typical consumption of

about 7 Watt when deployed (depending on deployment set-up). Additionally, these systems have options for

battery power, using 400W-hr alkaline or 800W-hr lithium battery packs.

Low frequency systems have, 150 kHz and 75 kHz, have 12-32 and 36-72 VDC input requirements and 500 and 1000-Watt power consumption, respectively.

Low frequency systems have, 150 kHz and 75 kHz, have 12-32 and 36-72 VDC input requirements and 500 and 1000-Watt power consumption, respectively.

What is the maximum velocity that can be measured by the ADCP?

Standard RTI systems can measure velocities to ±5 m/s (16.4 ft/s), however in custom cases RTI (request must be

made at purchase) can provide instruments capable of measuring to ±20 m/s (65.6 ft/s).

Can I integrate an instrument into a ROV/AUV for subsurface navigation?

YES. If you are using a third party AUV or ROV you may already be using a RTI DVL. RTI provides standard

packaging rated from 50m to 6000m as well as an OEM package that consists of transducers and electronics that

can be integrated directly into the AUV pressure hull.

What is the measurement range of the products?

All instruments will have a measurement range determined by the acoustic frequency used by the system. The

table below presents instrument range based acoustic processing (Narrowband or Broadband) and functionality,

Profiling or Bottom-track.

Broadband – is an acoustic signal processing technique that yields highly accurate current velocity measurements, however broadband processing has a= decreased profiling range.

Narrowband – is an acoustic signal processing technique that yields noisy current velocity measurements, however narrowband processing increased profiling range.

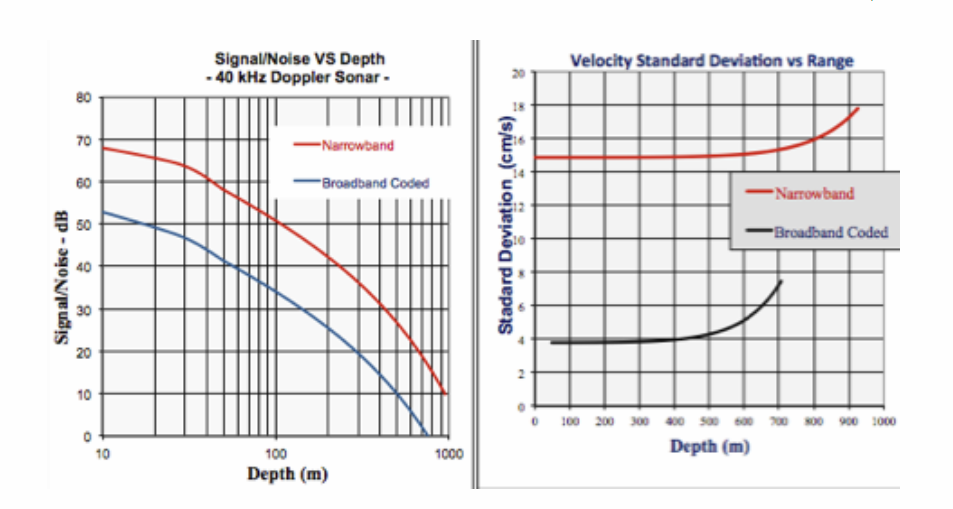

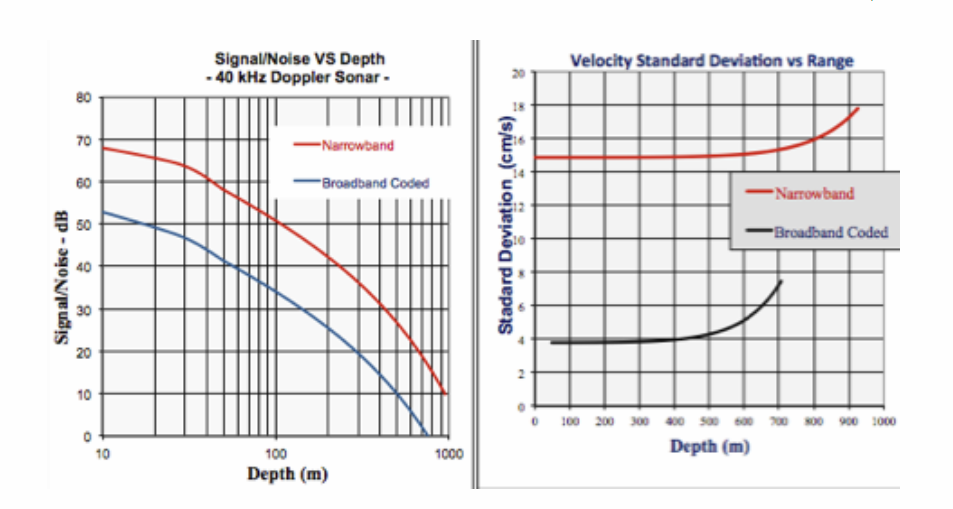

Bottom Track - is a method for measuring speed-over-ground in from a float platform such as a boat. The ADCP emits long acoustic pulses that are scattered by the bottom. Determining the Doppler shift in the returned echo provides a measure of the relative velocity between the ADCP/DVL and the bottom. This information is used to provide motion data required by the ADCP for its water-velocity measurements and navigation data to underwater vehicles The graphics below present the advantages and disadvantages of Broadband and Narrowband measurements.

Below is a graphic comparison of acoustic signal processing and depth as well\ as Standard Deviation of velocity measurement. It is important to note the increased profile range of Narrowband, however the quality of the velocity measurement is much less than the Broadband measurement.

|

Frequency (kHz) |

Profiling Broadband (m) |

Profiling Narrowband (m) |

Bottom Track Range (m) |

|---|---|---|---|

| 1200 | 20 | 30 | 50 |

|

600 (2")

|

45 | 70 | 120 |

|

600 (3")

|

50 | 75 | 130 |

| 300 | 100 | 150 | 300 |

| 150 | 370 | 450 | 700 |

| 75 | 590 | 750 | 1200 |

| 38 | 1100 | 1400 | 2200 |

Broadband – is an acoustic signal processing technique that yields highly accurate current velocity measurements, however broadband processing has a= decreased profiling range.

Narrowband – is an acoustic signal processing technique that yields noisy current velocity measurements, however narrowband processing increased profiling range.

Bottom Track - is a method for measuring speed-over-ground in from a float platform such as a boat. The ADCP emits long acoustic pulses that are scattered by the bottom. Determining the Doppler shift in the returned echo provides a measure of the relative velocity between the ADCP/DVL and the bottom. This information is used to provide motion data required by the ADCP for its water-velocity measurements and navigation data to underwater vehicles The graphics below present the advantages and disadvantages of Broadband and Narrowband measurements.

Below is a graphic comparison of acoustic signal processing and depth as well\ as Standard Deviation of velocity measurement. It is important to note the increased profile range of Narrowband, however the quality of the velocity measurement is much less than the Broadband measurement.

Can RTI ADCP/DVLs use Broadband acoustic signal processing?

YES. The Broadband patent expired in 2010 and Broadband Acoustic signal processing is incorporated into every

RTI instrument.

What is the maximum number of bins/cells that I can use for my deployment?

Regardless of instrument frequency each RTI ADCP has a maximum of 200 bin/cells for velocity profiling.

What velocity accuracy options does RTI have for the ADCP/DVLs?

RTI provides to accuracy options, high and low. The High accuracy option is accurate to 0.25% or ±2 mm/s, while

the low accuracy option is accurate to 1% or ±2 mm/s. RTI provide the 1% accuracy as a standard system; if the

high accuracy system is required, please be sure to mention when ordering.

How deep can the instruments be deployed?

RTI offers aluminum or titanium housings that can be deployed to 6000m.

How much memory does the system have and is there and internal battery?

Each RTI instrument has an 8 GB SD memory card. There is no internal battery that can be used for deploying the

instrument, however RTI does provide options for internal batteries for the self-contained product lines

(SeaWatch) as well as easy to integrate external battery packs. It is important to note that if a user has a

direct reading instrument (SeaPilot or SeaProfiler) external battery packs can be easily integrated to convert

the instrument into a self-contained system.

What communication protocols do RTI products use?

RTI uses RS232, RS485, RS422 and Ethernet to communicate with the instrument. The RS232, RS485 and Ethernet are

standard factory settings on Self-Contained systems. The Direct-Reading systems will come with Ethernet

optional. When placing your order if you would like Ethernet or RS422 please let us know and we can accommodate

this configuration.

How long can the cable be?

Cable lengths depend on the power source and the communication protocols. Using the RS422 protocol with a

appropriate power source cable lengths can be on the order of kilometers long.

How do I interface with an RTI ADCP/DVL?

RTI provides Pulse software with every purchase. The Pulse software

provides users a graphical user interface to connect, configure and deploy the instrument, as well as download

data and visualize data files. With the Pulse software, users are provided a terminal window that allows for

direct communication using commands defined in the user manual.

How do I know if my instrument is installed flat/level?

Every RTI instrument has an internal compass and pitch-roll sensor. The compass when calibrated can be used for

heading information, while the pitchroll sensor can be used to determine the quality of the installation by

interfacing with the software and outputting pitch-roll data in real-time or by graphing these same parameters

from historical data.

Do in need to make temperature corrections for speed of sound in water?

No. RTI provides an embedded and completely integrated temperature sensor. The temperature sensor measures in

real-time and is used to make speed of sound calculations for all of the collected data. To make sure that the

speed of calculations are correct be sure to input an accurate value for water salinity of the deployment site

– this is done in the Pulse software while interfacing and deploying the instrument.

Do you have any suggestions for antifouling for the instrument?

We suggest to use http://www.clearsignalcoating.com/.

You can have this coating put on during the purchasing process through us. Depending on the location in the

world, the ADCP can be sent to get coating on in transit to the final destnation after purchase.

Fouling is always a difficult problem to tackle and one thing is for sure, there are many interesting and different ways to combat biological fouling. For the body of the instrument we have heard many cases where duct tape wrapped around the outer housing is effective – upon recovery of the instrument the duct tape is removed along with the housing with new duct tape applied prior to re-deploying. The transducer face cannot be covered with duct tape. Effective antifouling techniques for the transducer are copper based paints; simply pain the face of the transducer with the copper based paint and allow to dry prior to deployment. Antifouling measures for cables is always a difficult task – in many cases the antifouling protect creates more work than the fouling itself. RTI recommends contacting a local University for antifouling techniques cables and for additional strategies for the housing and transducer face. Prior to applying antifouling measures, always check with RTI to confirm that the technique is appropriate for the instrument support@rowetechinc.com.

Fouling is always a difficult problem to tackle and one thing is for sure, there are many interesting and different ways to combat biological fouling. For the body of the instrument we have heard many cases where duct tape wrapped around the outer housing is effective – upon recovery of the instrument the duct tape is removed along with the housing with new duct tape applied prior to re-deploying. The transducer face cannot be covered with duct tape. Effective antifouling techniques for the transducer are copper based paints; simply pain the face of the transducer with the copper based paint and allow to dry prior to deployment. Antifouling measures for cables is always a difficult task – in many cases the antifouling protect creates more work than the fouling itself. RTI recommends contacting a local University for antifouling techniques cables and for additional strategies for the housing and transducer face. Prior to applying antifouling measures, always check with RTI to confirm that the technique is appropriate for the instrument support@rowetechinc.com.

More detailed FAQ can be found at our WIKI. Also more

topics, suggestions and user guides can be found at the same location.